iRobot’s Andrew Edzenga ’15 Meets with Upper School Robotics Students

On Wednesday, December 9, Andrew Edzenga ‘15, Test Engineer with iRobot, visited with students in Michael Omilian’s MFS Robotics course. With great enthusiasm, Andrew shared his educational and career path with students, reflecting on his personal and professional growth while also offering tips for college success. He has a B.S. in mechanical engineering from The George Washington University.

Andrew spent the time to compile a very organized presentation for students which covered a broad range of topics. He discussed with the students the need to continuously “build your skill tree.” He also encouraged students to seek out strong mentors, as well as strong teammates – whether that be at school, at work, or in their personal life. He reinforced the importance of surrounding yourself with good people.

Andrew detailed his impressive work with George Washington University Engineering’s SAE Mini Baja team which designs, builds, and races their car in national off-road competitions. “This is where I learned to apply all my engineering knowledge and jump ahead of my classmates and learn about topics you learn later in your career,” he said.

Andrew’s mentor during his work with the Baja team was a naval captain which, in turn, led to a research internship during his junior year with the U.S. Navy. He worked aboard a Navy vessel on designing and fabricating support systems for data collection on the “Impact of Ship Air Wakes on Rotary Aircraft” research team.

The following summer he worked for his “dream company” Tesla in a summer facilities engineering internship. He moved to California and mentioned to students that the experience provided him with great insight as to what areas he wanted to venture into professionally, mainly by observing employees at all levels at the famous electric vehicle and clean energy company.

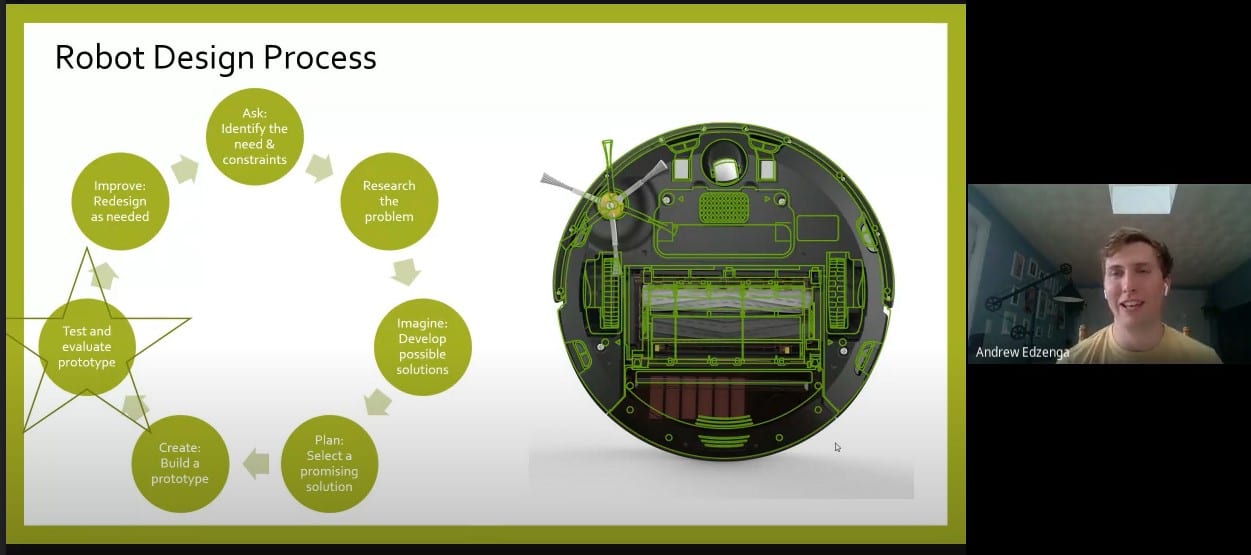

He concluded his presentation by discussing his current work with iRobot which designs and builds robot vacuums and robotic mops. Andrew compared the process of creating these products to a musical symphony. “It takes a lot of different kinds of engineers to make a robot just like it takes a group of musicians to make a symphony,” he concluded. He stepped through the robot design process and provided great technical insight for students. “I work on the test development team, so essentially I solve problems and find answers by any means necessary,” said Andrew. He also described the many different colleagues with whom he must collaborate throughout the design process.